Cyclo reducers-which is short for cycloidal reducers-are a variation of speed reducers that are designed to lower motor speed through an increase in torque and a decrease in output speed. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

Cleveland Gear Co. has specialized in speed control technology including a variety of quality manufactured speed reducers since 1912. We have successfully developed speed reducers for material handling, mineral processing, and more. You will find that our products have uncompromising quality, making all others less than the best. We will fulfill your exact requirements and that's what continues...

At JHFOSTER, we pride ourselves on our commitment to excellence in engineering and innovation. Our company specializes in designing and manufacturing high-performance speed reducers that cater to a wide range of industries. Our products are crafted with precision and reliability in mind, ensuring they meet the rigorous demands of modern industrial applications.

Apex Dynamics, Inc. is a worldwide leader in manufacturing of planetary gearboxes. Based on more than twenty years of accumulated manufacturing and marketing experience, plus the highest level of technical production capabilities, Apex Dynamics, Inc. designed and built a technically advanced, high speed, low backlash servo application planetary gearbox.

We manufacture highly advanced cyclo reducers which utilize new modifications which allow for 2-speed capabilities. This new technology efficiently provides a high amount of torque at a low speed. Our engineers put a focus on developing the most innovated and cost efficient solutions. We take pride in saying that we are an industry leader that is a global supplier. Feel free to give one of our...

More Cyclo Reducer Manufacturers

Cyclo reducers gain their effectiveness through use of a round disc that rotates off center, slowing the input speed and bringing it down to a more manageable level, useful or necessary for components that receive the output. These mechanisms are generally identified by the ratio of the input speed to the output speed called the reduction ratio.

Cyclo reducers are capable of providing high reduction ratios with high accuracy while remaining a compact size; they are generally ineffective at achieving ratios below 50:1, a ratio other devices such as shaft mounted speed reducers cannot reach in a single stage. They are constructed out of and housed in heavy duty steel or other strong metals, such as aluminum or cast iron.

Cyclo reducers are used within material handling, automotive, aerospace, recreational, construction, food and beverage processing, oil and gas and textile industries. They assist in automation equipment, conveyors, presses, pumps, generators and robotics and are frequently used in boats with propellers.

A cyclo reducer is made up of an input shaft, an eccentrically mounted bearing, a cycloidal disc, ring pins, output rollers and an output shaft. The input shaft drives the bearing that turns the disc. Because it is mounted eccentrically, the disc does not rotate around a single center point but rotates off center, closer to some ring pins than others. Output rollers fit through holes that are slightly larger in diameter than the rollers in order to achieve a steady rotation of the output shaft from the wobbling movement of the disc. The lobes around the disk's edge correspond with the ring pins that are attached to the chassis except that there is one more pin than there are lobes; this causes the cycloidal disc to rotate around the bearing faster than the rotation of the input shaft and in the opposite direction.

The ratio of the input speed to the reduced output speed is equal to the number of ring gear pins minus the number of lobes on the cycloidal disc divided by the number of lobes on the disc, written in a formula as R=(P-L)/L. Cyclo reducers are similar to other speed reducing mechanisms such as gear drives and reduction gears except that unlike many others, the input and output shafts cannot be reversed because the disc will not rotate correctly.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

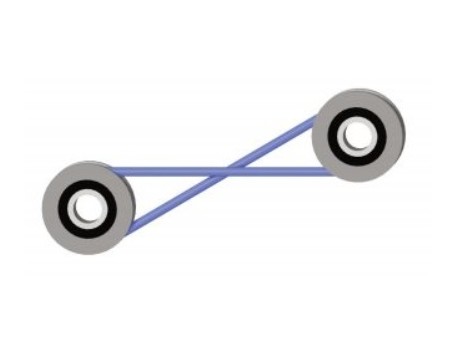

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services