A gear reducer, also called a gearbox, connects a motor mechanically to a driven load. Gear reducers enable the change of torque and speed of a system with respect to the load. A collection of gears make up a reduction gear assembly. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

Cleveland Gear Co. has specialized in speed control technology including a variety of quality manufactured speed reducers since 1912. We have successfully developed speed reducers for material handling, mineral processing, and more. You will find that our products have uncompromising quality, making all others less than the best. We will fulfill your exact requirements and that's what continues...

At JHFOSTER, we pride ourselves on our commitment to excellence in engineering and innovation. Our company specializes in designing and manufacturing high-performance speed reducers that cater to a wide range of industries. Our products are crafted with precision and reliability in mind, ensuring they meet the rigorous demands of modern industrial applications.

Apex Dynamics, Inc. is a worldwide leader in manufacturing of planetary gearboxes. Based on more than twenty years of accumulated manufacturing and marketing experience, plus the highest level of technical production capabilities, Apex Dynamics, Inc. designed and built a technically advanced, high speed, low backlash servo application planetary gearbox.

We manufacture highly advanced cyclo reducers which utilize new modifications which allow for 2-speed capabilities. This new technology efficiently provides a high amount of torque at a low speed. Our engineers put a focus on developing the most innovated and cost efficient solutions. We take pride in saying that we are an industry leader that is a global supplier. Feel free to give one of our...

More Gear Reducer Manufacturers

How Gear Reducers Work

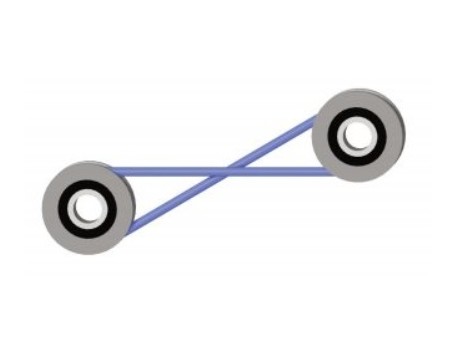

Gear reducers are required for high-efficiency machinery that operates at high speeds. The speed produced by the machinery must be adjustable to fit the required speed. A gear reducer comprises a large gear positioned next to a smaller gear, and both turn together.

When a large gear is coupled with a smaller gear in a single reducer system, the smaller gear produces twice as many revolutions for every singular turn of the larger gear. Speed increases as torque decreases with the repeated spins of the smaller gear.

The gear reduction process takes place at specified ratios of the driver and driven gear. The energy shift is achieved by changing the ratio of the moving gears in a gear reducer.

Types of Gear Reducers

The types of gear reducers include:

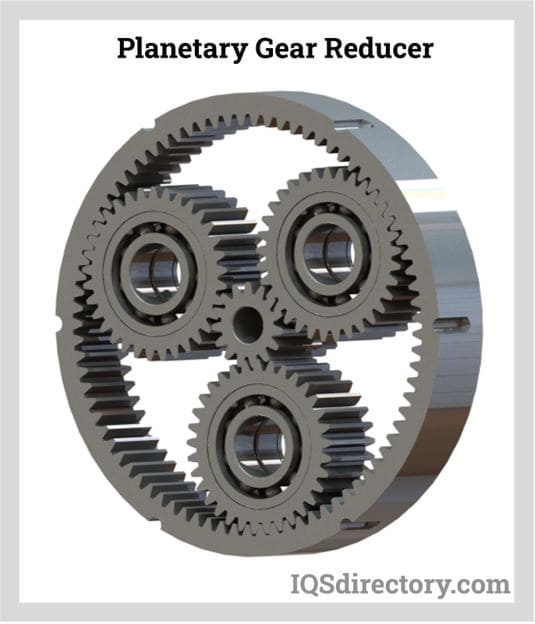

Planetary Gear Reducer

A planetary gear reducer contains a sun gear, planet gears, and a huge ring gear. The output shaft, inner gear ring, and sun gear support the planet gears. The sun gear in the middle of the gear configuration is driven by the power, which causes the planetary gears to rotate in lockstep with the inner gear ring.

The planet gears rotate the output shaft attached to the output power. A planetary reducer has a long service life, large carrying capacity, and high output torque, and it is compact, quiet, and efficient. In addition, it has power splitting and multiple teeth meshing, making it a versatile reduction.

Helical Gear Reducer

Helical gear reducers are another type of space-saving gear reducer with great overload capacity and durability. They're employed for forward speeds with a medium to high gear train.

Helical gears' tooth traces are slanted, resulting in a higher meshing ratio that reduces noise and increases strength. Their synchromesh design provides increased surface area and never disengages.

The helical cut of helical gears has an angular cut that allows the teeth to be longer while maintaining the same number of teeth as a spur gear.

Magnetic Gear Reducers

Magnetic gear reducers are a type of gear reducer that uses magnetic attraction rather than physical contact to reduce torque. They don't have gear teeth; instead, they use opposing magnets that oppose each other, allowing them to apply pressure from any angle.

Magnetic gears work the same way as traditional gears, but they don't touch; thus, they're not impacted by wear. Magnetic gears also don't require any lubrication or sealed barriers. Instead, they are made with permanent magnets or electromagnets.

Spur Gear Reducers

Spur gear reducers feature teeth that are parallel to the axis and have straight teeth. They are the most popular and widely used gear reducer, and they can contain multiple gears with different gear ratios. Spur gear gearboxes are extremely efficient, have little backlash, and are durable and stable.

Bevel Gear Reducers

An angular bell crank on bevel gear reducers allows users to adjust the system's rotation from transverse to longitudinal. They're small and powerful, with three-phase asynchronous motors, synchronous motors, and asynchronous servo motors providing the power.

Bevel gear reducers, like helical and hypoid gear reducers, work quietly while providing excellent performance and energy economy.

Worm Gear Reducers

A worm gear reducer consists of a worm pinion input and a right-angle output worm gear. Worm gear reducers are used to reduce the speed of a motor and provide a higher torque output at a lower speed. Worm gear reducers are perfect for reducing space because of their sleek shape, tiny output gear diameter, and excellent speed reduction they provide in a small container.

Hypoid Gear Reducers

Hypoid gears are cone-shaped gears that transmit power between shafts that do not intersect. Because the small hypoid pinion side is offset from the hypoid gear side, they can pass without colliding. Hypoid gears have a high contact ratio, transmitting higher load while maintaining smooth meshing.

Hypoid gears make less noise than helical gear reducers because of their smooth meshing. Hypoid gear reducers can lower speeds to extremely low levels. When the angle is square, and the distance between the axes is small, hypoid gears are commonly utilized. Hypoid gears are a type of gear that sits halfway between bevel and worm gears.

Choosing the Correct Gear Reducer Manufacturer

To make sure you have the most positive outcome when purchasing gear reducers from a gear reducer manufacturer, it is important to compare at least 4 to 5 companies using our list of gear reducer manufacturers. Each gear reducer manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each gear reducer business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple gear reducer companies with the same quote.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services