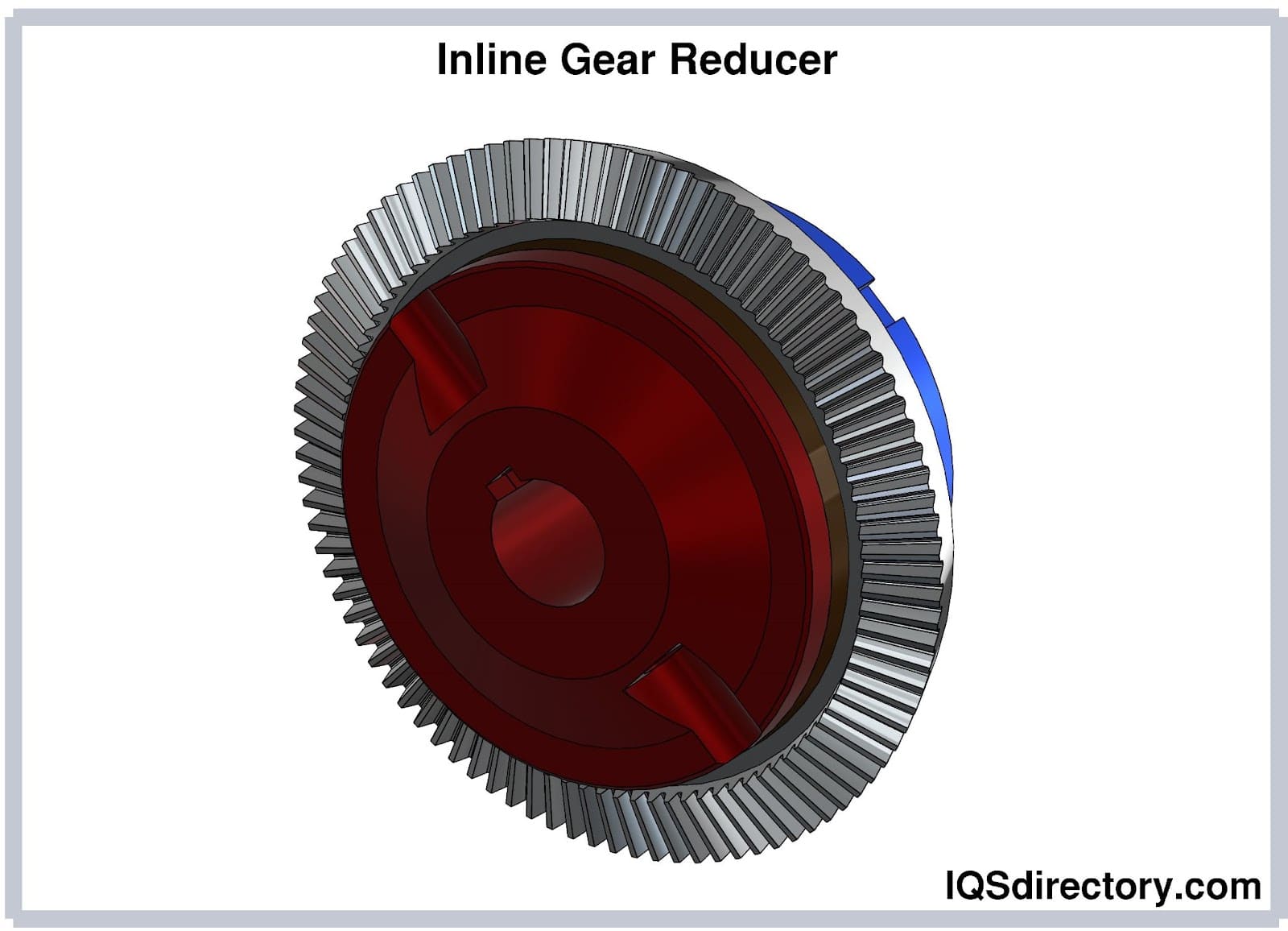

Inline gear reducers are used in a system with other components in order to decrease the incoming speed and power so that the parts that follow are able to handle the power and operate effectively. An inline gearbox’s input and output shafts have the same orientation, even if they may or may not be offset. Unlike other gearbox layouts, where the gearbox output shaft may be at right angles to the input shaft, an inline gearbox transmits torque in the same direction as the motor. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

Cleveland Gear Co. has specialized in speed control technology including a variety of quality manufactured speed reducers since 1912. We have successfully developed speed reducers for material handling, mineral processing, and more. You will find that our products have uncompromising quality, making all others less than the best. We will fulfill your exact requirements and that's what continues...

Onvio has manufactured high precision components and solutions for over 35 years. Our line of products includes speed reducers, planetary gears, and more. We also provide integrated subassemblies and complete systems. We are committed to working alongside our customers in order to ensure that they achieve their ideal design goals while staying within their budget. Whether your industry is in...

TNE, Inc. provides quality products and services, specializing in new, surplus, used and rebuilt Falk gear reducers. Visit us online to search our inventory of over 1,000 gearboxes, worm gears, right angle gear boxes, etc. Because of our quality work, all of our rebuilt equipment has a one year warranty.

Rexnord is a custom manufacturer and distributor of power transmission and conveying components including gearboxes, gear motors, right angle gear boxes and right angle speed reducers. With more than 100 years of experience, service and technical support, Rexnord gears maximize performance while lowering total cost of ownership.

More Inline Gear Reducer Manufacturers

Inline gearboxes are classified as parallel or coaxial, and each uses a distinctive gear arrangement with its own set of advantages and disadvantages.

How Inline Gear Reducers Work

A motor rotates the input shaft at a set speed, and a sequence of reduction gears slows the rotational speed. Depending on the reduction ratio, the diameter and circumference of the gears vary. A gear revolves on an input shaft, which turns a larger gear. The second gear takes longer to rotate the full distance due to its larger circumference and does not turn as quickly as the little first gear. Multiple gears can be connected in series, and the output shaft connected to the final gear to achieve the desired speed reduction.

Although greater performance speed reducers are available, reduction ratios typically range from 5:1 to 200:1. A gearhead is a gear reducer that is directly mounted on a motor; a gearbox is a gear reducer that is linked with the shaft and mounted elsewhere. Units that are installed on the shaft are also available. Inline gear reducers can be used in conjunction with other reducers to satisfy specific needs, and they come in a range of styles to fit a variety of mountings and setups.

Types of Inline Gear Reducers

The types of inline gear reducers include:

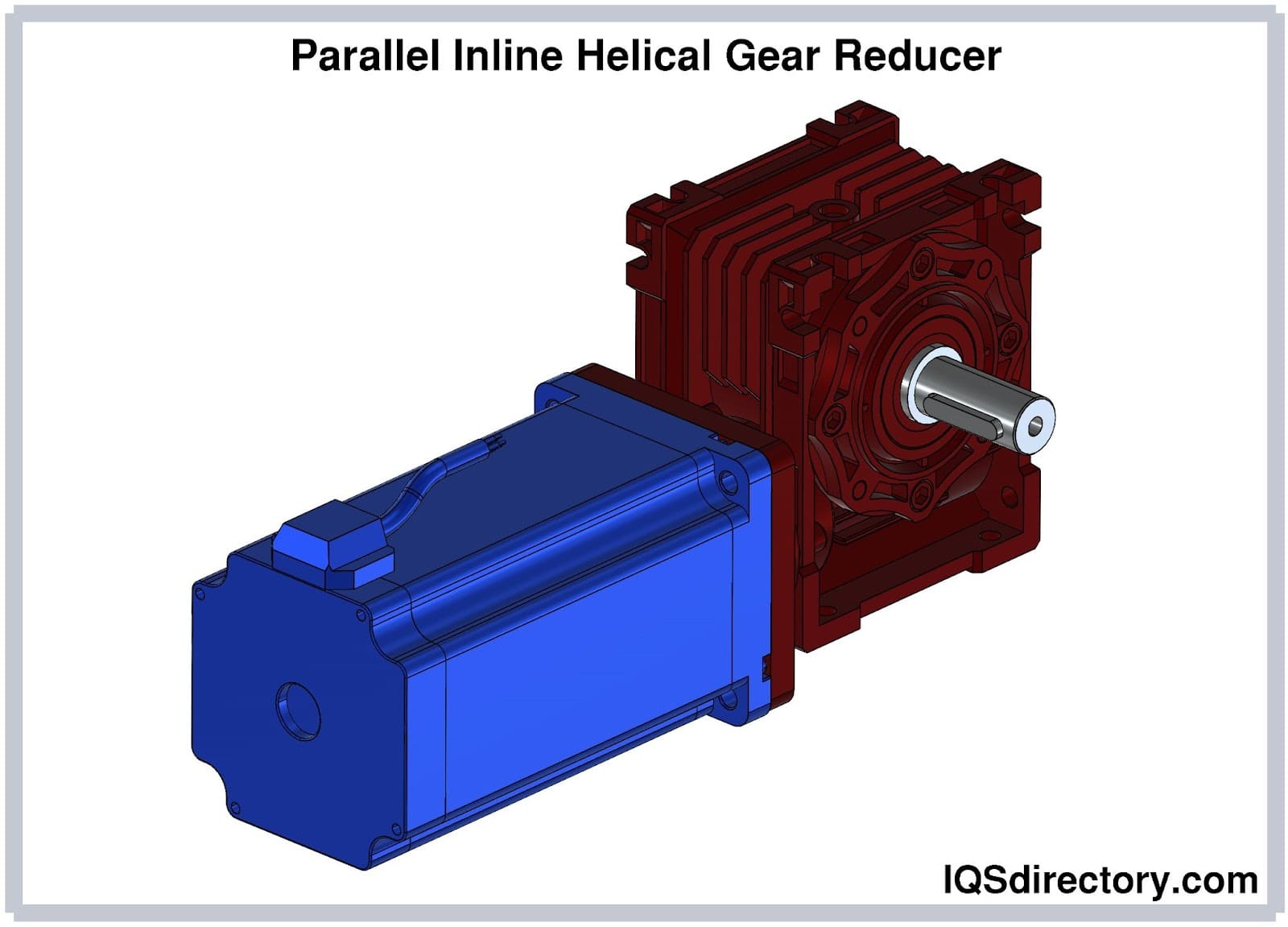

Parallel Inline Gear Reducers

The input and output shafts of a parallel inline gearbox are oriented in the same direction but offset by a certain distance, resulting in shaft axes that are parallel to each other. Spur, helical, and double helical gear types are commonly used in parallel gearboxes.

Helical Gear Reducers

Helical gears contain teeth that run diagonally, which increases the meshing surface area between gear teeth and the number of teeth in contact, allowing the gearbox to handle more torque. Helical gears produce thrust forces along the shaft axis, which can put significant stress on bearings. While helical gears have far better all-around performance characteristics than spur gears, with far higher torque capability and somewhat quieter operation, they produce thrust forces along the shaft axis, which can put significant stress on bearings. Depending on the pressure, this may necessitate unique techniques to sustain the load, and their power transmission capability is reduced compared to double helical gears.

Double Helical Gear Reducers

Helical gears generate thrust, which can shorten the life of gearboxes. Double helical gears use a gear that looks like two opposing helical gears positioned side by side to deal with the thrust force created. Twice helical gear systems double the high torques of helical gears while retaining the benefits of helical gears.

Spur Gear Reducers

The simplest gear is a spur gear, which has straight teeth that protrude radially from the gear center. Despite their inexpensive cost, spur gear systems have a lot of noise, backlash, and torque transmission capabilities. In addition, because of the small surface area of the gear teeth, they are subjected to significant stresses; therefore, this gear system is designed for low-speed, low-torque applications.

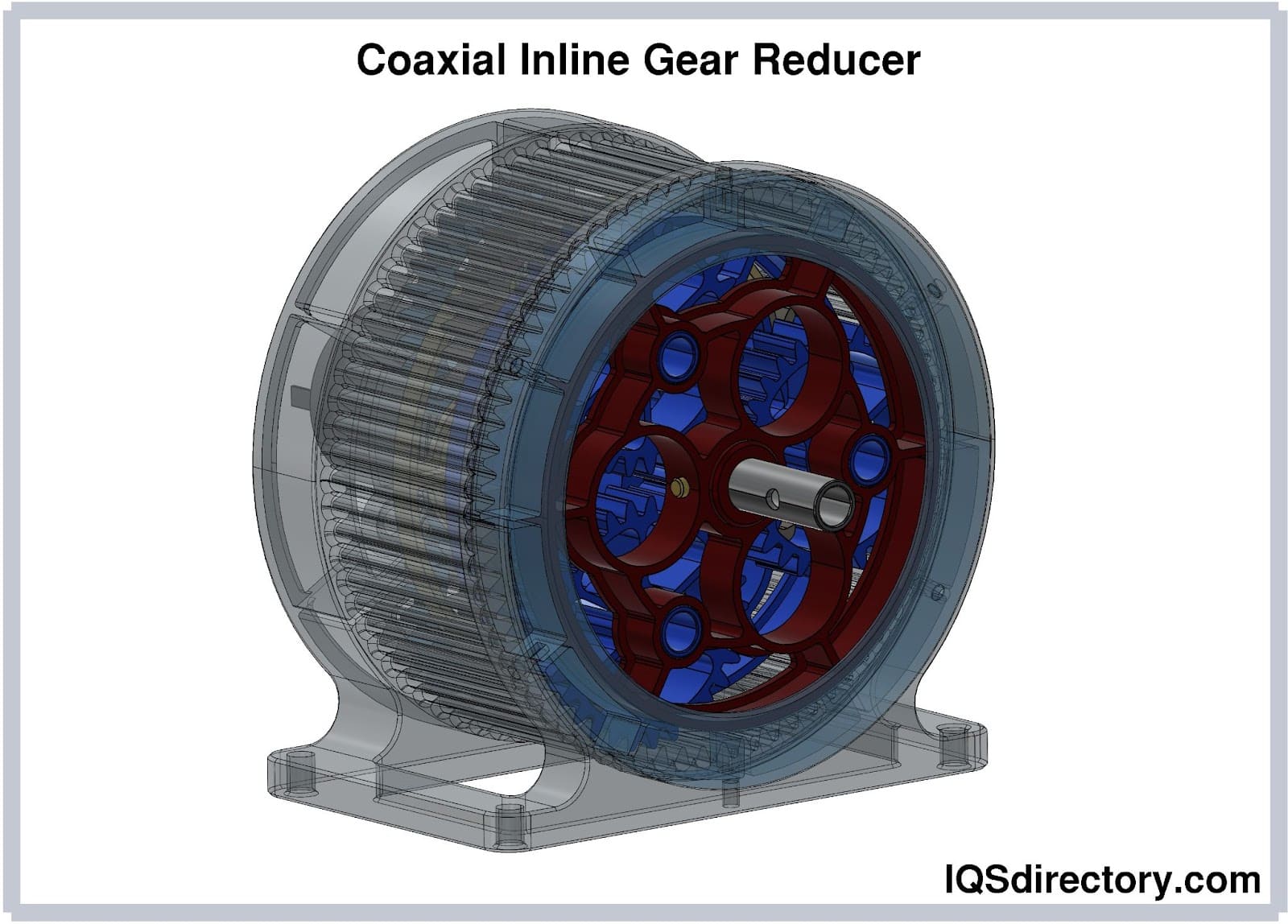

Coaxial Inline (Planetary) Gear Reducers

A coaxial inline gearbox's input and output shafts are aligned along the same line with no position offset, allowing the motor, gearbox, and load to revolve around the same axis. Planetary gear systems are used in these gearboxes. A planetary gear system is a relatively sophisticated gear design that uses a collection of gears (referred to as "planet" gears) that rotate around a single gear in the center (referred to as the "sun" gear).

This gear design enables high reduction ratios in a compact dimension by transmitting great torque along a straight axis with perfect balance. Planetary gearboxes are great for improved acceleration and high precision applications because they can be coupled in stages to obtain high reduction ratios. They also have little backlash.

Choosing the Proper Inline Gear Reducer Supplier

To make sure you have the most productive outcome when purchasing inline gear reducers from an inline gear reducer supplier, it is important to compare at least 4 companies using our list of inline gear reducer suppliers. Each inline gear reducer supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each inline gear reducer company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple companies with the same form.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

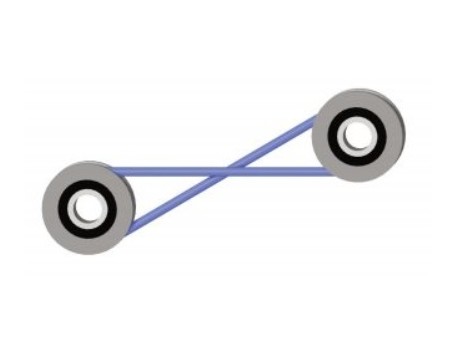

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services