A gear is a device that transfers power from one shaft to another. A set of gears and their case, most frequently seen in automobiles, are simply referred to as “gear boxes.” Transmissions enable machinery to run effectively and even help slow down and shut down machinery because most motor vehicle engines have high operating and idling speeds. Gearboxes move energy from one spinning power source to another in cars, turbines, and other large machines. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

Cleveland Gear Co. has specialized in speed control technology including a variety of quality manufactured speed reducers since 1912. We have successfully developed speed reducers for material handling, mineral processing, and more. You will find that our products have uncompromising quality, making all others less than the best. We will fulfill your exact requirements and that's what continues...

At JHFOSTER, we pride ourselves on our commitment to excellence in engineering and innovation. Our company specializes in designing and manufacturing high-performance speed reducers that cater to a wide range of industries. Our products are crafted with precision and reliability in mind, ensuring they meet the rigorous demands of modern industrial applications.

Apex Dynamics, Inc. is a worldwide leader in manufacturing of planetary gearboxes. Based on more than twenty years of accumulated manufacturing and marketing experience, plus the highest level of technical production capabilities, Apex Dynamics, Inc. designed and built a technically advanced, high speed, low backlash servo application planetary gearbox.

We manufacture highly advanced cyclo reducers which utilize new modifications which allow for 2-speed capabilities. This new technology efficiently provides a high amount of torque at a low speed. Our engineers put a focus on developing the most innovated and cost efficient solutions. We take pride in saying that we are an industry leader that is a global supplier. Feel free to give one of our...

More Gearbox Manufacturers

Types of Gearboxes

Gearboxes are classified into industrial and automobile gearboxes.

Industrial Gearboxes

Worm Reduction Gearboxes

Heavy-duty operations are driven by worm reduction gearboxes. These gearboxes are employed when greater speed reduction is required between axis shafts that are not intersecting. This gearbox uses a large-diameter worm wheel. The teeth on the outside of the gearbox mesh with the worm. The wheel moves in the same direction as the worm. The majority of these industrial gearboxes are employed in large industries including minerals, chemicals, and fertilizers.

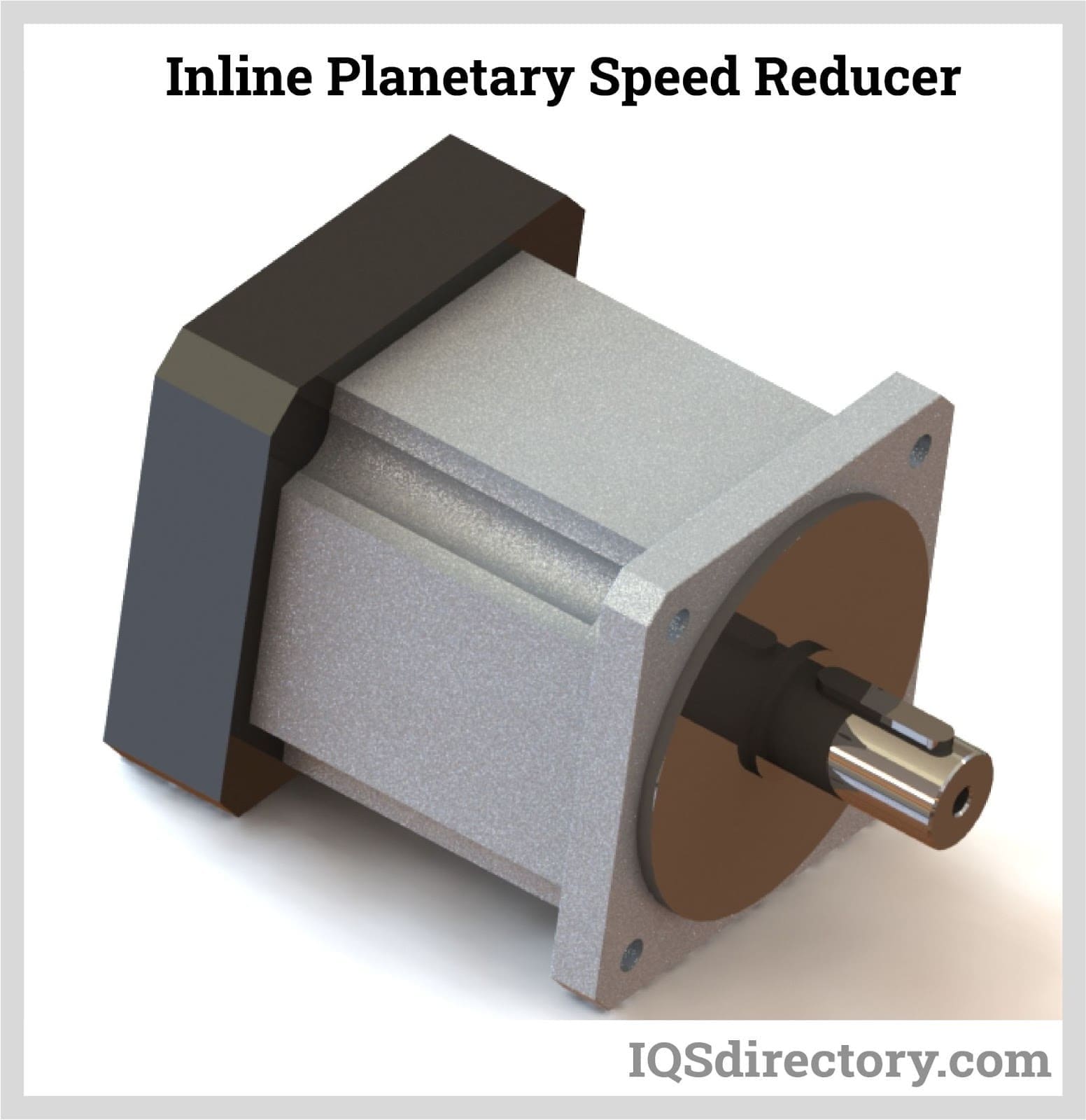

Planetary Gearboxes

Three of the four planet gears circle the center sun gear in a planetary gearbox. All of these are connected by an outer ring gear with internal teeth. A planetary gear system can generate a lot of torque in a short amount of space because of this design, which evenly distributes the power through the gears. The planetary gearbox excels in precision applications because of its durability, precision, and unique functionality. This kind of gearbox extends equipment life and improves performance. Planetary gearboxes are available with a range of mounting choices, such as a flange, shaft, or foot, as well as in solid or hollow formats.

Coaxial Helical Inline Gearboxes

Heavy-duty applications benefit greatly from the coaxial helical gearbox. Coaxial helical inlines are renowned for their effectiveness and high caliber. These are produced to a very high standard, allowing users to increase load and transmission ratios.

Bevel Gearboxes

A curved collection of teeth on the cone-shaped surface at the unit's rim is the crucial component of this kind of gearbox. A bevel-helical gearbox is used to provide rotary motion between non-parallel shafts. These are frequently utilized in mining operations, quarries, and conveyors.

Skew Bevel Helical Gearboxes

The strong, monolithic design of the skew-bevel helical gearbox makes it useful for heavy loads and other applications. Once they are installed on the proper motor shaft output, these industrial gearboxes offer mechanical advantages. Based on the number of teeth and gears, these can be made to fit any need.

Automobile Gearboxes

Under automobile gearboxes they are classified into manual and automatic transmission.

Manual Transmission Gearboxes

Constant Mesh Gearboxes

Constant-mesh transmissions, also referred to as synchronized transmissions, maintain constant motion in the drive gear, cluster gear, and main shaft gears. The fact that the gears can freely rotate around the main shaft makes this possible. When necessary, a dog clutch is employed to lock these gears into position. The dog clutch and main shaft gears' teeth lock onto each other when the shift linkage moves, holding the gear in place. In constant-mesh transmissions, synchronizers are employed to stop any grinding or clashing during shifting.

Pre-Selector Gearboxes

As automobile manufacturers experimented with design, manual transmissions underwent a succession of evolutions and modifications, as with everything else. The Wilson pre-selector was an early form of manual transmission created before automated transmissions were commonplace. A tiny lever on the steering column was used to preselect gear ratios in this transmission, which utilized a planetary gear system. The driver depresses a foot pedal to select a gear by pressing down on one of the preselected ones. The old gear disengages at the same moment that the new one engages when this occurs.

Automatic Transmission Gearboxes

Automated-Manual Transmission Gearboxes

The automated-manual transmission is a kind of automatic transmission that has a typical clutch and gear layout but incorporates sensors, actuators, processors, and pneumatics to mimic the use of manual gears. Even though these cars are known for their jerky acceleration and poor engine performance at low speeds, they get great gas mileage on long trips.

Torque Converter Gearboxes

The most popular kind of automatic gearbox transmits the rotational force of the engine to the wheels using a torque converter. Although there is some efficiency loss as it takes up drive due to the curved shape of the turbine blades inside the converter, a torque converter is a fluid coupling that allows the car to pull away and stop without stalling the engine. This type of transmission can speed up smoothly at low speeds and respond well when the engine revs are low.

Choosing the Proper Gearbox Manufacturer

To make sure you have the most productive outcome when purchasing gearboxes from a gearbox manufacturer, it is important to compare at least 4 companies using our list of gearbox companies. Each gearbox manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each gearbox company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple gearbox companies with the same quote.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

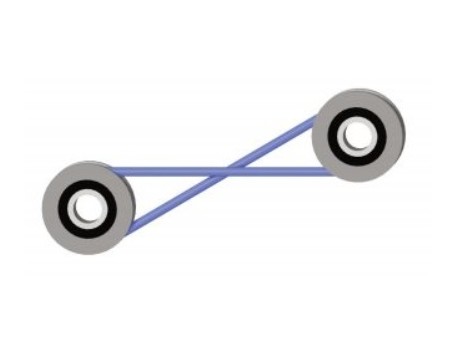

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services