Right-angle gearboxes use rotation to transmit power at a 90-degree angle between the driveshaft and the output shaft. Many mechanical designs, such as car transmissions, use right-angle gearboxes. Gearboxes could have a ratio of 1:1 or a multiple of 1, like 2:1 or 15:1. When the ratio is 1:1, the drive is right-angled. Whenever the ratio exceeds 1:1, a right-angle speed reducer is used. Read More…

We offer premium speed reducers and motion control components. These deluxe parts are designed for a wide range of purposes and our engineers are willing to assist you with determining the best speed reducer.

Cleveland Gear Co. has specialized in speed control technology including a variety of quality manufactured speed reducers since 1912. We have successfully developed speed reducers for material handling, mineral processing, and more. You will find that our products have uncompromising quality, making all others less than the best. We will fulfill your exact requirements and that's what continues...

At JHFOSTER, we pride ourselves on our commitment to excellence in engineering and innovation. Our company specializes in designing and manufacturing high-performance speed reducers that cater to a wide range of industries. Our products are crafted with precision and reliability in mind, ensuring they meet the rigorous demands of modern industrial applications.

Apex Dynamics, Inc. is a worldwide leader in manufacturing of planetary gearboxes. Based on more than twenty years of accumulated manufacturing and marketing experience, plus the highest level of technical production capabilities, Apex Dynamics, Inc. designed and built a technically advanced, high speed, low backlash servo application planetary gearbox.

We manufacture highly advanced cyclo reducers which utilize new modifications which allow for 2-speed capabilities. This new technology efficiently provides a high amount of torque at a low speed. Our engineers put a focus on developing the most innovated and cost efficient solutions. We take pride in saying that we are an industry leader that is a global supplier. Feel free to give one of our...

More Right Angle Gear Box Manufacturers

Types of Right Angle Gearboxes

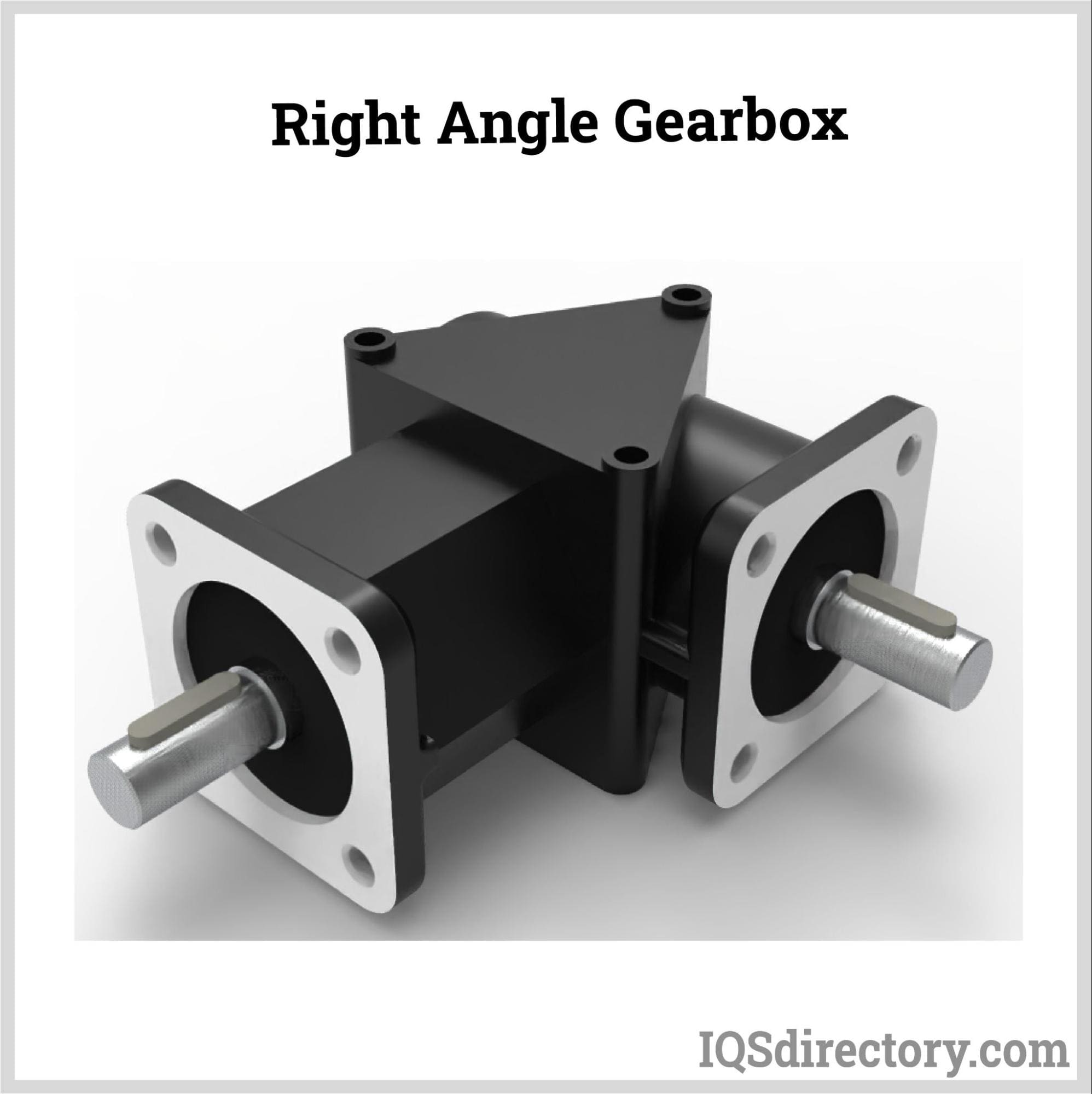

Two-Way Right Angle Gearbox

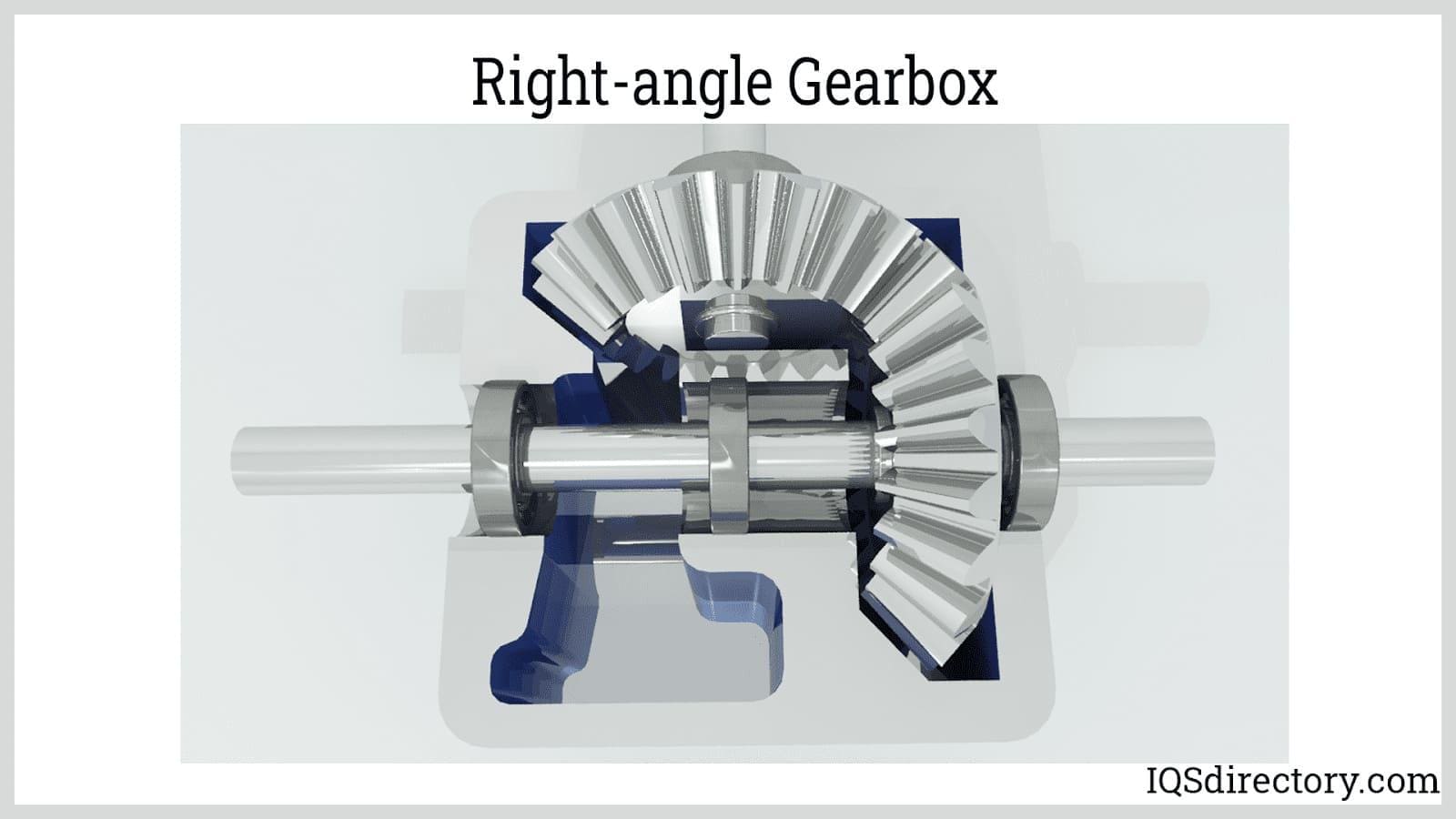

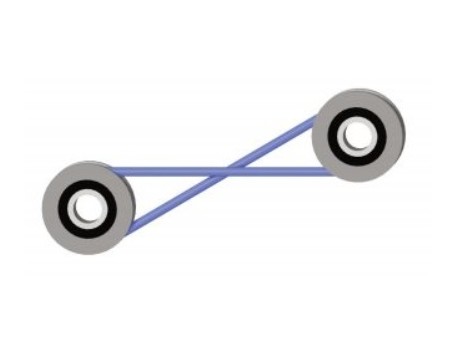

Two shafts are positioned, so the power transmission creates a 90-degree turn in two-way right-angle gearboxes. As a result, right-angle drives are perfect for situations with limited space and where the driven equipment must be close to one another. In addition, the right-angle gearbox design enables smooth power transfer with less backlash and changes in axis rotation. As a result, power transmission is dependable using right-angle drives.

The two-way 90-degree drives use precisely crafted, hardened spiral bevel gears that rotate corrosion-resistant stainless steel shafts or plastic shafts to transfer power silently and smoothly. The enclosed casing of right-angle power transmission gearboxes ensures that the internal gears won't become misaligned, jam, or harmed by pollutants. In addition, the lightweight housing has excellent heat dissipation and strong strength.

Three-Way Right Angle Gearboxes

One input shaft and two output shafts make up three-way right-angle gearboxes, which provide simple 90-degree power transmission. This design enables smooth power transfer with less backlash and fluctuations in axis rotation. In addition, three-way right-angle gearboxes have long-lasting, maintenance-free spiral bevel gears that operate quietly for reliable speed or power transfer. Spiral bevel gears that have been hardened to AGMA Class 10 and non-magnetic stainless steel shafts are standard on gear motors.

Counter-Rotating Right Angle Gearbox

Two output shafts are on the same axis in counter-rotating gearboxes, with one input shaft 90 degrees apart from both outputs. The two output shafts of a counter-rotating gearbox concurrently revolve in opposite directions, which makes for the perfect counterweight. In mechanical drive systems, a counterbalanced spinning gearbox helps dampen vibrations and adds to the stability.

Any power transmission application that wants to increase load efficiency and lessen wear on mechanical components should use counter rotating right-angle gearboxes. A gearbox's increased production, performance, and smoother operation are further advantages. In addition, changes in axis rotation are possible with the counter-rotating design, and backlash is kept to a minimum.

These speed reducers convey quiet, steady power through non-magnetic stainless steel shafts and reinforced spiral bevel gears. Furthermore, small and with a variety of mounting possibilities are counter-rotating gearboxes. The enclosed design prevents the internal gears from misaligning, jamming, or getting clogged with debris. The drives come in 1:1 and 2:1 ratios and have shafts that are 3/8", 1/2", 5/8", and 3/4" in diameter.

IP65-Rated Right Angle Gearbox

Include stainless steel shafts, shaft seals, nickel-plated cast aluminum housings, and especially created hardened spiral bevel gears. These units are perfect for applications requiring frequent washdowns, such as those in the food sector, and have been tested and verified for the IP65 classification by an independent laboratory. In addition, all models offer a lengthy, maintenance-free life because they are permanently lubricated with a high H1 food-grade grease.

Considerations When Choosing a Right Angle Gearbox

- Choose the ratio of input to output that you prefer. The usual ratios are 1 to 1 and 2 to 1. For example, shaft #2 can be used as the input shaft on 2:1 units for a step-up ratio of 1:2.

- Select the shafts that will serve as the input and output shafts. This stage is essential to establish that no shaft will rotate at a speed of more than 2000 RPM. For example, shaft #2 in the 2:1 ratio versions can turn at a maximum speed of 1000 RPM if that shaft is chosen as the input shaft. It doesn't matter in the 1:1 ratio models. The decision, in either instance, will have an impact on the mounting.

- Select the drive type. Either a 2-way or 3-way arrangement should be used.

- Choose a standard model and an IP65 ingress protection/nickel-plated model if necessary.

- Choose the appropriate model number. Be aware that units with 3/8-inch shafts have flats, whereas those with 1/2-, 5/8-, 3/4-, and 1-inch shafts have standard keyways when choosing a model number. Also, note that versions with 1-inch shafts are only available in three-way types.

- Ensure the output shaft produces more torque than the application's required load.

Choosing the Proper Right-Angled Gearbox Company

To make sure you have the most positive outcome when purchasing right-angled gearboxes from a right-angled gearbox company, it is important to compare at least 4 to 5 manufacturers using our right-angled gearbox directory. Each right-angled gearbox company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each right-angled gearbox business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple right-angled gearbox companies with the same quote.

Ball Bearings

Ball Bearings Ball Screws

Ball Screws Electric Motors

Electric Motors Friction Materials

Friction Materials Gears

Gears Quick Release Couplings

Quick Release Couplings Shaft Couplings

Shaft Couplings Speed Reducers

Speed Reducers Timing Belting

Timing Belting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services